Square Cast Iron Lapping Plates with Handles are made of high duty grey Cast Iron (C.I), they are heat treated to relieve internal stresses; and available in square, rectangular and round types; cast iron lapping plates are extensively used for lapping parts to extreme flatness in low volumes in laboratory, toolroom or maintenance workshops.

OEM or ODM service: we offer a wide range of services from standard surface plates to custom order as per request.

Calibration Certificate: EX-works inspection reports offered by our Quality Inspection Department are included with every surface plate, “Calibration Certificate” is available upon request for an additional charge.

Delivery Costs: calculated during the checkout process.

As a professional CI surface plates manufacturer, Hengfeng Measuring Tools can produce square cast iron lapping plates with precision grades 0, 1, 2, and 3, or even fine machining standards, ensuring accuracy and reliability in use. The cast iron surface plates can be customized to feature rib plates or box types, with working surfaces available in rectangular, square, or round shapes.

Square cast iron lapping plates features:

• Manufactured from high quality cast iron.

• Rigid ribbed structure

• Thick & solid top surface

• Precisely finished by planning and hand scraping

• Accuracy acc. to IS2285-2003/ DIN 876

• Custom sizes are welcome as per request.

Material: HT200-300 or customized

Specification: 200x200 up to 4000x8000mm or customized

Working Surface: flat, grid slots for location, tapped holes, T-slots, etc.

Hardness: HB160-240

Structure: ribbed (bone) structure with enough wall thickness

Surface Coating: working surface covered with antirust oil and unmachined areas covered with antirust paint

Heat-treated: available for stress relief, stability and wear resistance

Accessories: supplied with suitable arrangement for leveling and anchoring on the floor.

Stands with Leveling Screws: available for corresponding sizes and supplied at extra cost, if required. Total height from floor to the top of the surface plate is approx. 750 to 800mm.

Handles: Surface Plates up to 500 x 500 mm provided with handles for lifting at extra cost, if request.

Precision grade: 0-3

Packaging: anti-rust packing+ plywood box

Warranty: 1 year

Standard Sizes of Surface Plates / Tables

| No. | SizeWidth*Length (mm) | Precision Grade | |||

| GR “0” | GR “1” | GR “2” | GR “3” | ||

| Flatness (μm) | |||||

| 1 | 200x200 | 3.5 | 7 | 14 | |

| 2 | 300x200 | 4 | 8 | 15 | |

| 3 | 300x300 | 4 | 8 | 15 | |

| 4 | 300x400 | 4 | 8 | 16 | |

| 5 | 400x400 | 4.5 | 8.5 | 17 | |

| 6 | 400x500 | 4.5 | 9 | 18 | |

| 7 | 400x600 | 5 | 10 | 19 | |

| 8 | 500x500 | 5 | 10 | 19 | |

| 9 | 500x600 | 5 | 10 | 19 | |

| 10 | 500x800 | 5.5 | 11 | 21 | |

| 11 | 600x800 | 5.5 | 11 | 22 | |

| 12 | 600x900 | 6 | 11.5 | 23 | |

| 13 | 1000x750 | 7 | 12.5 | 25 | 50 |

| 14 | 1000x1000 | 7 | 13.5 | 27 | 54 |

| 15 | 1000x1200 | 14 | 29 | 58 | |

| 16 | 1000x1500 | 16 | 32 | 63 | |

| 17 | 1000x2000 | 18.5 | 37 | 74 | |

| 18 | 1500x2000 | 20 | 40 | 80 | |

| 19 | 1500x2500 | 22.5 | 45 | 90 | |

| 20 | 1500x3000 | 25 | 50 | 100 | |

| 21 | 2000x2000 | 22 | 44 | 88 | |

| 22 | 2000x3000 | 27 | 53 | 106 | |

| 23 | 2000x4000 | 32 | 64 | 127 | |

| 24 | 2000x5000 | 37 | 75 | 150 | |

| 25 | 2000x6000 | 43 | 86 | 172 | |

| 26 | 2000x7000 | 49 | 97 | 194 | |

| 27 | 2000x8000 | 54.5 | 109 | 218 | |

| 28 | 2500x3000 | 28.5 | 57 | 114 | |

| 29 | 2500x4000 | 33 | 67 | 133 | |

| 30 | 2500x5000 | 39 | 77 | 154 | |

| 31 | 2500x6000 | 88 | 176 | ||

| 32 | 2500x7000 | 99 | 198 | ||

| 33 | 2500x8000 | 110 | 221 | ||

| 34 | 3000x3000 | 61 | 122 | ||

| 35 | 3000x4000 | 70 | 140 | ||

| 36 | 3000x5000 | 80 | 160 | ||

| 37 | 3000x6000 | 90.5 | 181 | ||

| 38 | 3000x7000 | 101 | 203 | ||

| 39 | 3000x8000 | 112.5 | 225 | ||

| 40 | 4000x4000 | 78 | 156 | ||

| 41 | 4000x5000 | 87 | 174 | ||

| 42 | 4000x6000 | 96.5 | 193 | ||

| 43 | 4000x7000 | 107 | 213.5 | ||

| 44 | 4000x8000 | 117 | 235 | ||

*Other sizes & combinations can be manufactured as per requirement.

Square Cast Iron Lapping Plate with Handles

Square Cast Iron Lapping Plate with Handles

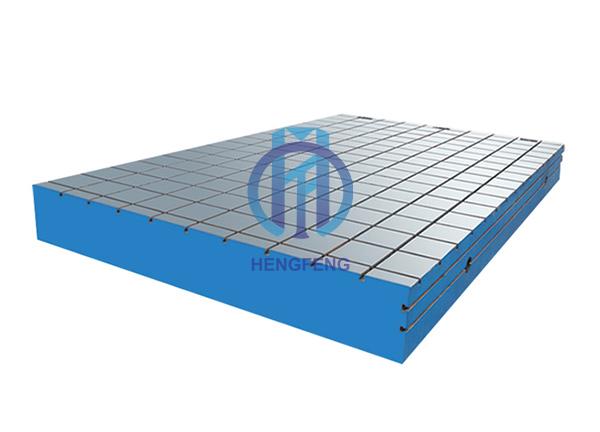

Antirust Cast Iron Surface Plate

Antirust Cast Iron Surface Plate

Surface Plates For Testing

Surface Plates For Testing

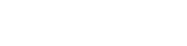

Cast Iron T slotted Bed Plate

Cast Iron T slotted Bed Plate

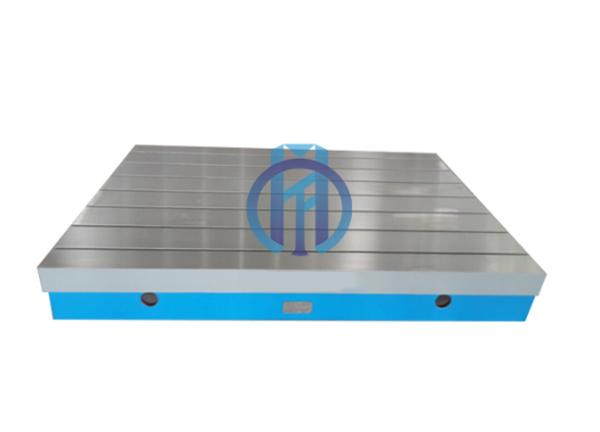

Cast Iron Surface Plate for Welding

Cast Iron Surface Plate for Welding

Cast Iron Surface Plate for Boring and Milling Machine

Cast Iron Surface Plate for Boring and Milling Machine

Hand Scraped Cast Iron Surface Plate

Hand Scraped Cast Iron Surface Plate

Cast Iron Surface Plate

Cast Iron Surface Plate

Precision Round Type Surface Plate (For Lapping)

Precision Round Type Surface Plate (For Lapping)