Antirust cast iron surface plates are made from good quality close grained high duty grey Cast Iron (C.I), heat treatment is available to relieve internal stresses. Furter more, the cored and ribbed structure help to increase the structural rigidity to bear the heavy loads. Cast iron flat surface plates provide a precision reference or datum plane for spotting, tool marking, inspection of workpieces, checking accuracy of other surfaces, for many types of gauging and marking out (layout) operation.

Cast iron surface plates are used in conjunction with accessories such as cast iron angle plate, cast iron square box, cast iron square ruler, cast iron right angle ruler, cast iron straight edge, etc.

OEM or ODM service: we offer a wide range of services from standard surface plates to custom order as per request.

Calibration Certificate: EX-works inspection reports offered by our Quality Inspection Department are included with every surface plate, “Calibration Certificate” is available upon request for an additional charge.

Delivery Costs: calculated during the checkout process.

To enhance the platform's rust prevention capabilities, Hengfeng Measuring Tools places special emphasis on surface treatment during the manufacturing process. Our cast iron T-slotted surface plates are coated with antirust oil on the working surface, while the unmachined areas are painted with antirust paint, collectively providing an additional layer of corrosion protection.

The application of this antirust oil and paint not only slows down the corrosion process but also protects against moisture, oxygen, and other elements that cause rust. The cast iron plates, after such surface treatment, are better protected in humid and salty environments, thus extending their service life and maintaining their precision.

The surface hardness of the cast iron surface tables ranges from HB160 to HB240, which further enhances their wear resistance and ensures stable and reliable performance in a variety of industrial applications.

• Manufactured from high quality cast iron.

• Rigid ribbed structure

• Thick & solid top surface

• Precisely finished by planning and hand scraping

• Accuracy acc. to IS2285-2003

• Custom sizes are welcome as per request.

Material: HT200-300 or customized

Specification: 200x200 up to 4000x8000mm or customized

Working Surface: flat, grid slots for location, tapped holes, T-slots, etc.

Hardness: HB160-240

Structure: ribbed (bone) structure with enough wall thickness

Surface Coating: working surface covered with antirust oil and unmachined areas covered with antirust paint

Heat-treated: available for stress relief, stability and wear resistance

Accessories: supplied with suitable arrangement for leveling and anchoring on the floor.

Stands with Leveling Screws: available for corresponding sizes and supplied at extra cost, if required. Total height from floor to the top of the surface plate is approx. 750 to 800mm.

Handles: Surface Plates up to 500 x 500 mm provided with handles for lifting at extra cost, if request.

Precision grade: 0-3

Packaging: anti-rust packing+ plywood box

Warranty: 1 year

Standard Sizes of Surface Plates / Tables

| No. | SizeWidth*Length (mm) | Precision Grade | |||

| GR “0” | GR “1” | GR “2” | GR “3” | ||

| Flatness (μm) | |||||

| 1 | 200x200 | 3.5 | 7 | 14 | |

| 2 | 300x200 | 4 | 8 | 15 | |

| 3 | 300x300 | 4 | 8 | 15 | |

| 4 | 300x400 | 4 | 8 | 16 | |

| 5 | 400x400 | 4.5 | 8.5 | 17 | |

| 6 | 400x500 | 4.5 | 9 | 18 | |

| 7 | 400x600 | 5 | 10 | 19 | |

| 8 | 500x500 | 5 | 10 | 19 | |

| 9 | 500x600 | 5 | 10 | 19 | |

| 10 | 500x800 | 5.5 | 11 | 21 | |

| 11 | 600x800 | 5.5 | 11 | 22 | |

| 12 | 600x900 | 6 | 11.5 | 23 | |

| 13 | 1000x750 | 7 | 12.5 | 25 | 50 |

| 14 | 1000x1000 | 7 | 13.5 | 27 | 54 |

| 15 | 1000x1200 | 14 | 29 | 58 | |

| 16 | 1000x1500 | 16 | 32 | 63 | |

| 17 | 1000x2000 | 18.5 | 37 | 74 | |

| 18 | 1500x2000 | 20 | 40 | 80 | |

| 19 | 1500x2500 | 22.5 | 45 | 90 | |

| 20 | 1500x3000 | 25 | 50 | 100 | |

| 21 | 2000x2000 | 22 | 44 | 88 | |

| 22 | 2000x3000 | 27 | 53 | 106 | |

| 23 | 2000x4000 | 32 | 64 | 127 | |

| 24 | 2000x5000 | 37 | 75 | 150 | |

| 25 | 2000x6000 | 43 | 86 | 172 | |

| 26 | 2000x7000 | 49 | 97 | 194 | |

| 27 | 2000x8000 | 54.5 | 109 | 218 | |

| 28 | 2500x3000 | 28.5 | 57 | 114 | |

| 29 | 2500x4000 | 33 | 67 | 133 | |

| 30 | 2500x5000 | 39 | 77 | 154 | |

| 31 | 2500x6000 | 88 | 176 | ||

| 32 | 2500x7000 | 99 | 198 | ||

| 33 | 2500x8000 | 110 | 221 | ||

| 34 | 3000x3000 | 61 | 122 | ||

| 35 | 3000x4000 | 70 | 140 | ||

| 36 | 3000x5000 | 80 | 160 | ||

| 37 | 3000x6000 | 90.5 | 181 | ||

| 38 | 3000x7000 | 101 | 203 | ||

| 39 | 3000x8000 | 112.5 | 225 | ||

| 40 | 4000x4000 | 78 | 156 | ||

| 41 | 4000x5000 | 87 | 174 | ||

| 42 | 4000x6000 | 96.5 | 193 | ||

| 43 | 4000x7000 | 107 | 213.5 | ||

| 44 | 4000x8000 | 117 | 235 | ||

*Other sizes & combinations can be manufactured as per requirement.

*Large sizes can be made by joining plates along sides together to make required overall area.

Cast Iron Precision Surface Plate

Cast Iron Precision Surface Plate

Floor Type Boring and Milling Machine Workbench

Floor Type Boring and Milling Machine Workbench

Precision Round Type Surface Plate (For Lapping)

Precision Round Type Surface Plate (For Lapping)

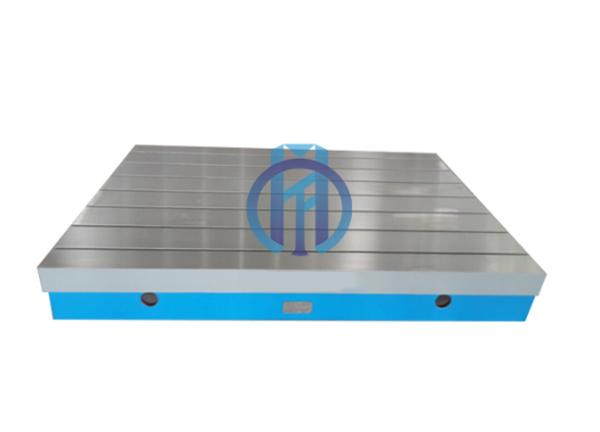

Cast Iron Surface Plate

Cast Iron Surface Plate

Hand Scraped Cast Iron Surface Plate

Hand Scraped Cast Iron Surface Plate

Cast Iron Surface Plate for Boring and Milling Machine

Cast Iron Surface Plate for Boring and Milling Machine

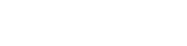

Cast Iron Surface Plate for Welding

Cast Iron Surface Plate for Welding

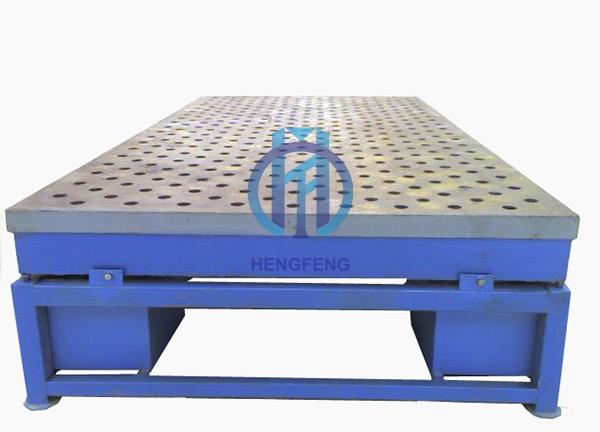

Cast Iron T slotted Bed Plate

Cast Iron T slotted Bed Plate

Surface Plates For Testing

Surface Plates For Testing

Antirust Cast Iron Surface Plate

Antirust Cast Iron Surface Plate